Power Supply – Solution for Predictive Maintenance of Uninterruptible Power Supply Devices

Tuesday, 22.11.2022.

Tuesday, 22.11.2022.

00:34

00:34

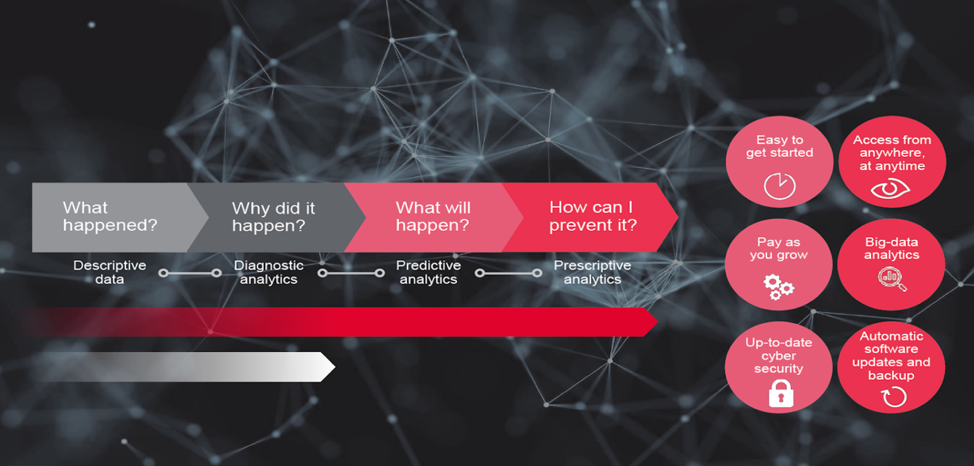

That is why ENEL PS decided to take a huge step in the direction of digital transformation of the service sector by developing a platform for predictive maintenance of equipment.

What is predictive maintenance?

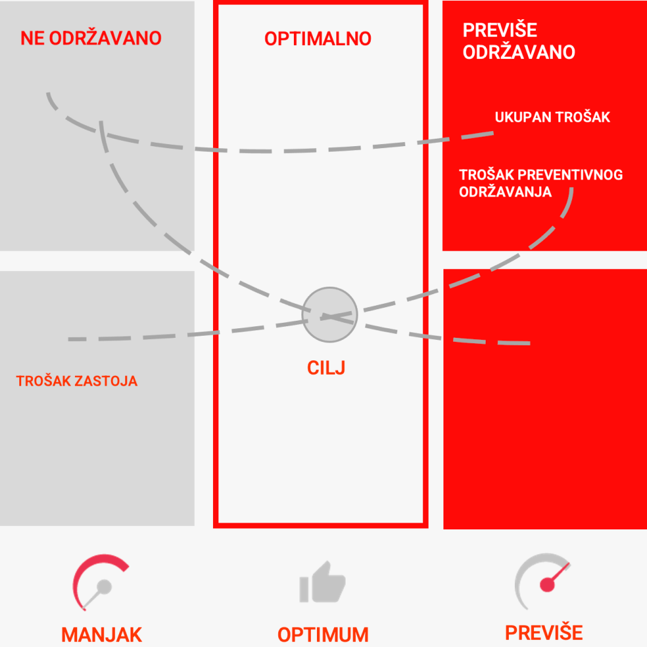

Predictive maintenance is the most advanced type of equipment maintenance that consistently monitors the equipment and processes wide range of interconnected data about the condition of the equipment which results in predictions about the future condition of the equipment so that any potential failures can be prevented before they happen.

With Power Supply platform, ENEL PS`s goal is to help clients entirely eliminate delays in workflow caused by power supply failure and consequently eliminate costs caused by delays, provide the possibility of creating detailed maintenance cost plans and optimize consumption of electric energy or possibly spent but unused electric energy in factories.

ENEL PS d.o.o. Beograd

ENEL PS d.o.o. Beograd

Naš izbor

Rafting, Hiking, Canyoning – Highlander Camp organizes team building activities that are retold many times Tourism, Sports, Culture

Healing hot water and affordable lodging prices in Josanicka Banja attract skiers from Kopaonik Energy, Tourism, Sports, Culture, Healthcare

Most Important News

06.04.2024. | Agriculture

Preconditions for Placement of Fresh Blueberries and Dried Plums in Chinese Market Secured

16.04.2024. | News

Jovan Ciric, Leasing Director Retail MPC Properties – MPC Echo symbolizes our desire for good ideas and innovative endeavors to spread freely and bring about positive changes

16.04.2024. | News

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

Creative Industry – What This Serbian Economy Sector Worth EUR 2 Billion Encompasses

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

26.04.2024. | Industry, Construction

Plans for continuation of construction of Belgrade sewer system announced – Section beneath river Sava to be 414 meters long, reconstruction of Karaburma tunnel

26.04.2024. | Industry, Construction

16.04.2024. | News

Economy Fair in Mostar opens – 26 companies from Serbia exhibiting

16.04.2024. | News

26.04.2024. | Construction

CLS: Where is the Ada Huja bridge project?

26.04.2024. | Construction

Izdanje Srbija

Izdanje Srbija Serbische Ausgabe

Serbische Ausgabe Izdanje BiH

Izdanje BiH Izdanje Crna Gora

Izdanje Crna Gora

News

News