Green Construction in Serbia Which Doesn’t Even Recycle Building Waste – Utopia or Near Future

Friday, 27.05.2022.

Friday, 27.05.2022.

10:39

10:39

Energy efficiency is now something that goes without saying, so companies are going a step further. There’s talk about buildings that will be built so that they can be “disassembled” easily and so that all the materials can be reused later.

There’s a reason for the great demand for buildings without waste – at the moment, the construction industry worldwide is responsible for around 50% of the generated waste. It’s similar in Serbia, where the biggest share in the waste is comprised precisely of construction waste – as many as three quarters, according to certain data.

On the other hand, the recommendation of the European Union is for 70% of the construction waste to be recycled by 2024. How then to realize green construction in a country which doesn’t require even 5% of the waste?

Everything matters – from the design to the choice of materials

Dr Jelena Dragas, an assistant professor from the Faculty of Civil Engineering, notes that the phrases green, sustainable construction and carbon-neutrality are used as part of the popular environmental narrative, but that they have also become an essentially important part of the construction practice. As she says for the eKapija portal, the construction industry, on the global level, is responsible for the utilization of 50% of the used natural materials, 40% of the produced energy and 50% of the generated waste.

– By choosing the construction materials, we can influence a partial reduction of the use of natural resources and the amounts of the construction (or some other industrial) waste that is generated. Today, in addition to the physical and mechanical characteristics of a material, it is important to also know the ecological ones: how much energy it takes to get a certain material, or the raw material ready to be applied in construction (cement, steel reinforcement, bricks, thermal insulation…), the quantities of the greenhouse effect gases emitted during the production of those materials and their transport to the construction site, whether the material can be reused after the demolition of the facility, whether it can be recycled or whether it ends up at a landfill – notes Dr Dragas.

Our interviewee warns that, if we want to reduce the negative environmental impact of the construction industry, it is necessary to choose the optimal design, the most efficient materials with the lowest ecological effect, to design durable structures and implement the technologies and systems which consume the least energy.

– Green building needs to entail all these principles, from the first phase of creating the preliminary design, through the construction phase, during the utilization of the facility and after the completion of the usability period of that facility – Dr Dragas reminds.

Less than 5% of construction waste recycled in Serbia

The Ellen MacArthur Foundation also says that, today, it is necessary to take care of all the phases of construction. This foundation warns that, so far, the construction industry has been focused on energy efficiency in buildings, and that, if it wants to achieve true carbon-neutrality, it needs to deal with emissions related to the materials and the construction process.

Modular construction systems are recommended, which will enable the reuse of materials once the life cycle of the facility ends. The European Commission has also suggested to the construction sector to adopt the principles of circular design, to pay attention to the durability and the adaptability of facilities and to reduce waste.

– After the usability period of a facility ends, there is an important question of the further flow of the materials it is made of. The best way is to reuse those materials for the construction of a new facility (ideally on a local level) and it is metal that is most frequently used that way, due to its high economic value. If it is not possible to reuse a material, it is important to valorize it in some way or recycle it. In 2008, the European Union adopted Directive 2008/98/EC, which envisages the reaching of the reuse, valorization or recycling of at least 70% of non-hazardous construction waste (concrete, bricks, steel, plaster, timber…) by 2024. In the Republic of Serbia, there is no active scheme for recycling construction waste, and less than 5% of the waste is recycled – Dr Dragas says.

Higher fees for use of natural materials should be implemented

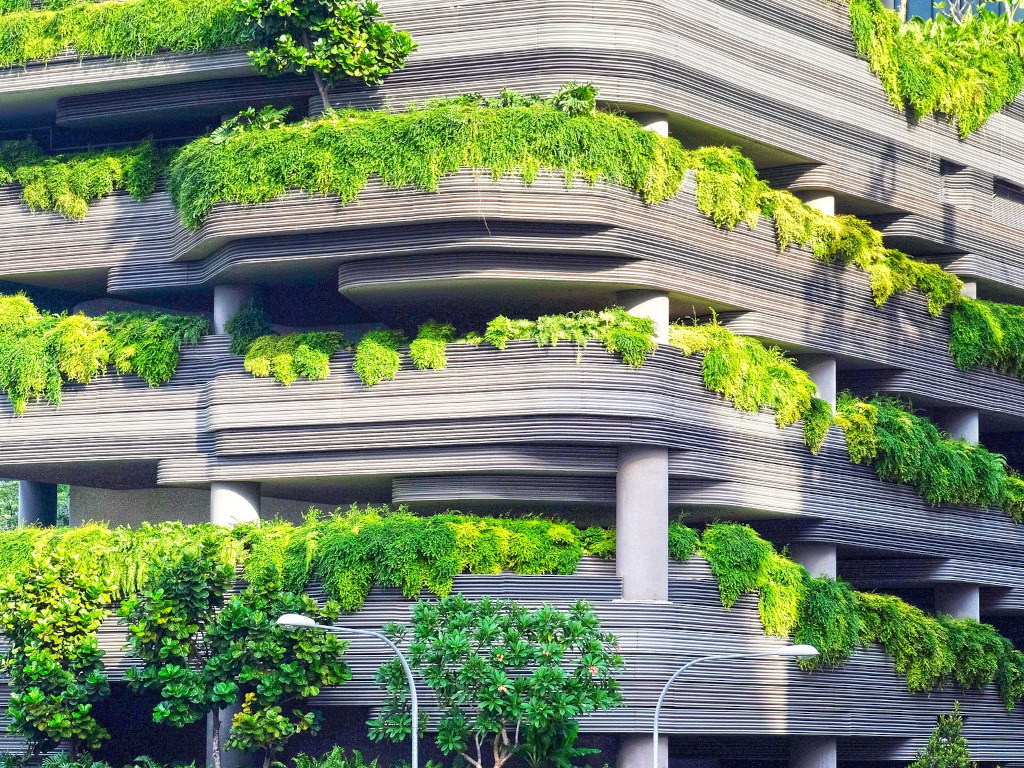

It is, nevertheless, possible to do things differently. The architects designing facilities based on the principles of honoring the environment plan, from the beginning, solar panels on the roof, as well as mechanism that will influence a reduction of waste. One of those mechanisms is the use of rainwater for the irrigation of the gardens within the facility, from which foodstuffs or spices for restaurants are produced. Recently, in France, a new law was passed, requiring all new office buildings to have their roofs partially covered by plants or solar panels.

The Green House in Utrecht, for example, is designed as a temporary facility, because the city plans to change the look of that neighborhood in the coming decades. That is why the pavilions can be fully “disassembled”, all the materials can be reused, and the structure is made so that there are no pipes and cables underground, which will leave the ground “clean” after the life cycle of the building ends.

Still, not even in the world are entirely green buildings a usual occurrence. Plenty of conditions need to be met for recycled materials to be used more in construction, to start with – from establishing a system for the treatment of construction waste, to enabling them to not be more expensive than non-recycled materials.

– The majority of construction and demolition waste is disposed of together with municipal waste at non-sanitary municipal landfills. The first condition for its recycling is an adequate management of that waste, its separation from municipal waste, a selective demolition of facilities and the establishment of a system for the treatment of that waste. In order for recycled materials to be able to compete with natural ones, higher fees for the use of natural materials should be implemented (if we want to keep them), waste disposal fees should be increased, subsidies for recycling facilities should be provided and business entities should be educated about the possibilities of the application of recycled materials – Dr Dragas points out.

Another challenge lies in the characteristics of recycled materials, but that challenge could be overcome, our interviewee believes.

– Plenty of research has been done in the field of implementation of various recycled and waste materials in the construction industry: recycled concrete aggregate, the use of fly ash and slag from blast furnaces in concrete, recycling bricks, steel, rubber, asphalt, glass, wood… In most cases, the recycling process changes the characteristics of the basic material, but by knowing those characteristics, we can find the best implementation of recycled materials in the construction of new facilities – points out Dr Dragas.

Concrete and asphalt can be recycled

Ministry of Construction: Mandatory use of recycled materials in new buildings should be implemented

As the Ministry of Construction, Transport and Infrastructure of Serbia says for the eKapija portal, considering the accelerated development of the construction sector in the past years, it is necessary to establish an adequate system for the management of construction and demolition waste.

– The plan is to prepare an analysis of the current state of handling construction and demolition waste and the potentials for recycling in the construction sector. Furthermore, education of the construction sector and the preparation of an expert guide on the proper handling of this waste, legislative requirements, as well as the economic effects of its use after recycling, are also planned. The reduction of the total amount of waste is achieved through recycling and the reuse of non-hazardous waste and the development of the market for that kind of waste. It is also achieved through a quicker implementation of the concepts of circular economy and through certain legal solutions (mandatory for certain segments). For example, making it mandatory for a finished product to contain a certain percentage of recycled materials, requesting for a certain percentage of recycled construction materials to be used for the construction of new buildings and so on – the ministry explains.

– If we don’t count earth, concrete comprises the majority of that waste. If pure concrete waste is separated, it can be ground, classified by fractions and used again as an aggregate of recycled concrete which either fully or partially replaces the natural aggregate in concrete. The characteristics of this aggregate differ from natural rock (somewhat higher absorption rate, higher resilience to wear-out, lower pressure firmness), but by knowing these special characteristics, an adequate implementation of concretes made from recycled aggregate in the construction industry can be done. There is enough research to cover all the levels of the implementation of recycled aggregate (as a 50-100% replacement of natural aggregate), which confirms its safe implementation in the construction of reinforced-concrete facilities – says Dr Dragas.

As our interviewee explains, in addition to concrete, asphalt is a material which can be recycled easily and efficiently. New roads could thereby be built from old ones.

– Due to the aging effects, crushed asphalt in new mixtures can generally increase the stiffness, resilience to rutting distress, reduce the resilience to the appearance of cracks and sensitivity to increased temperatures. However, with the application of chemical additives for recycling, the initial characteristics of the asphalt can be recovered to the largest extent, enabling its implementation in new mixtures (20-100% replacement) – concludes the assistant professor Dr Jelena Dragas.

Marija Dedic

Ministarstvo građevinarstva, saobraćaja i infrastrukture Republike Srbije

Ministarstvo građevinarstva, saobraćaja i infrastrukture Republike Srbije

Građevinski fakultet Beograd

Građevinski fakultet Beograd

Naš izbor

Most Important News

06.04.2024. | Agriculture

Preconditions for Placement of Fresh Blueberries and Dried Plums in Chinese Market Secured

16.04.2024. | News

Jovan Ciric, Leasing Director Retail MPC Properties – MPC Echo symbolizes our desire for good ideas and innovative endeavors to spread freely and bring about positive changes

16.04.2024. | News

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

Creative Industry – What This Serbian Economy Sector Worth EUR 2 Billion Encompasses

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

26.04.2024. | Construction

CLS: Where is the Ada Huja bridge project?

26.04.2024. | Construction

16.04.2024. | News

Economy Fair in Mostar opens – 26 companies from Serbia exhibiting

16.04.2024. | News

25.04.2024. | Construction, Transport

Railroad from Novi Sad to Subotica connected – Regular traffic at year’s end

25.04.2024. | Construction, Transport

Izdanje Srbija

Izdanje Srbija Serbische Ausgabe

Serbische Ausgabe Izdanje BiH

Izdanje BiH Izdanje Crna Gora

Izdanje Crna Gora

News

News