Eko Bio Invest Soon to Start Producing Innovative Material from Which Fully Degradable Products Will Be Made – Alternative to Thin, Single-Use Plastic (PHOTO, VIDEO)

Monday, 05.12.2022.

Monday, 05.12.2022.

11:19

11:19

– We have a partner company in Paris which does the commercialization of this material, as well as a company in Zagreb, in which the granulate will be produced. The research department is in Belgrade and, in partnership with the Institute of Molecular Genetics and Genetic Engineering (IMGGE), it is working on further upgrading the material for new applications, testing regional raw materials and the possibilities of the re-use of the final products made from our material (up-cycling) – our interviewee says.

She adds that, so far, the possibility of getting the biopigment for the textile and, to a certain extent, the use as a fertilizer have been confirmed:

– We strive to provide access to clients throughout Europe in the best way possible, to learn about their needs, so that we would be able to guarantee the optimal, quality service, for numerous applications.

The production of the granulate and the foils will begin in January 2023 in Zagreb, and the expansion of capacities in Belgrade is planned for next year.

How Is the Granulate Made?

The granulate is based on the fruit and vegetable waste that is generated in the food preparation process or the process of the preparation of these ingredients.

– It is important to emphasize that food waste, which, in urban conditions, comprises up to 50% of the waste in landfills, is picked up at the place where it is generated, so it doesn’t even reach the landfill, which not only reduces its quantities, but also the emissions of CO2 and the easily flammable methane – Cvijanovic says.

She points out that the granulate could be made from fruit and vegetables too, but the company believes that it would be “an irresponsible and unnecessary practice, since there are already huge amounts of organic waste”.

– Practically all fruit and vegetable waste can be used for making the granulates using our patent-protected process. Depending on the type of ingredient, you get less or more granulate, and the utilization rate is greater in those which contain less water. IMGGE assesses every ingredient we want to test, which depends on the supplier with which we agree the delivery – eKapija’s interviewee clarifies.

The processing is done in several steps, and result is the granulate which is then used for making final products such as foils and bags, or any items that are currently made from thin, usually single-use plastic.

Alternative to Foils, Bags, Cups, Plates, Protective Equipment…

Said material is an alternative to everything that is currently made from thin, usually single-use plastic. Typical final products made from granulates are foils and bags, and cup and plate prototypes have also been made. They are also working on models of protective equipment.

– There are potential applications in the packaging industry, retail, medicine, pharmacy, cosmetics, agriculture and so on. There have already been inquiries from potential clients, mostly from the EU, for all said sectors. In the first years, we will certainly be oriented toward the region and the EU, and then also beyond it. I expect the wide application to first start in the packaging industry – the interviewee says.

Technology Confirmed by Certificates

Marina Cvijanovic says that the most important document that Eko Bio Invest has secured is the EU patent, which protects the process of the production of the material.

In addition to that, they got the “OK Compost Home” EU certificate, which proves that the material is fully degradable even in home conditions, that is, without the use of additives of disposal in specialized composting tubs. In water whose temperature is over 80 degrees Celsius, it dissolves in less than a minute, and in cold water or on/in the ground, in 25 days to six months.

– The usual practice in the EU and worldwide is for the level of the emission of carbon-dioxide to be determined for each production process, which is often an important criterion in choosing a business partner. For our material, we got the certificate which confirms that there are no CO2 emissions during the production process – the interviewee points out.

“Each of us should ask ourselves what the best practices are that could contribute to a healthier environment”

When asked how she sees the development of circular economy in Serbia, Marina Cvijanovic says that “changing awareness is always a long-lasting process, but it is important that Serbia has chosen to adopt the Green Agenda principles and that it is actively working on it”.

– The Action Plan has been prepared, the Program of Development of Circular Economy in Serbia Until 2024 has been adopted, there are efforts to harmonize the regulations with the Green Agenda, more and more workshops, panels and campaigns are organized on various levels, from companies which generate considerable amounts of waste, to schools, in order to encompass as wide a range of the society which is ready to adapt its behavior to environmental preservation. Each of us should ask ourselves what the best practices are that could contribute to a healthier environment, and which, with a little good will, we can easily implement each day, for better living conditions for all of us, which we certainly deserve – she concludes.

Aleksandra Kekic

Naš izbor

Most Important News

11.03.2024. | Healthcare

Are Marketing Experts Reading Our Minds? – eKapija Investigates: What Neuromarketing Is and How Much It Is Used in Serbia

11.03.2024. | Construction, Transport

Tender for Continuation of Construction of Patrijarha Pavla Blvd Stopped – Contractors Demanding Price Higher Than Estimated

11.03.2024. | Construction, Transport

11.03.2024. | Construction, IT, Telecommunications

Auction for 5G Network by End-Year, Minister Announces

11.03.2024. | Construction, IT, Telecommunications

15.04.2024. | Energy, Industry

Vinca Solid Waste Management Center to start producing heating and electrical energy in the next month

15.04.2024. | Energy, Industry

17.01.2024. | Industry, Healthcare

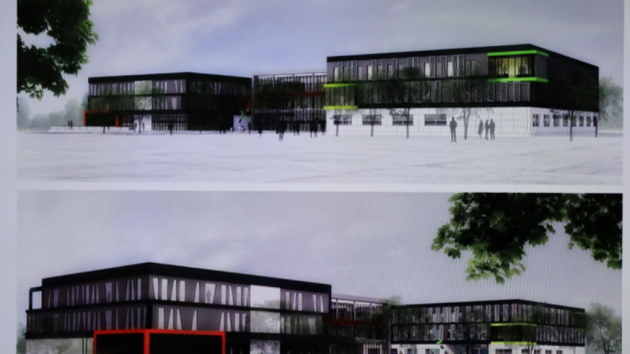

Ceremony of Opening of Centers of Excellence in Kragujevac Planned for Spring – Official Beginning of Operations in June

17.01.2024. | Industry, Healthcare

15.04.2024. | Construction, Transport, Finance

City approves signing of agreement with Ministry of Economy and BAS on continuation of financing of project of new bus station – EUR 20 million over two years

15.04.2024. | Construction, Transport, Finance

Izdanje Srbija

Izdanje Srbija Serbische Ausgabe

Serbische Ausgabe Izdanje BiH

Izdanje BiH Izdanje Crna Gora

Izdanje Crna Gora

News

News